In the framework of the FLEXnCONFU (FLEXibilize combined cycle power plant through power-to-x solutions using Non-CONventional FUels) European project, a dedicated test rig for ammonia synthesis production at low pressure and high flexibility as been developed.

Process Description:

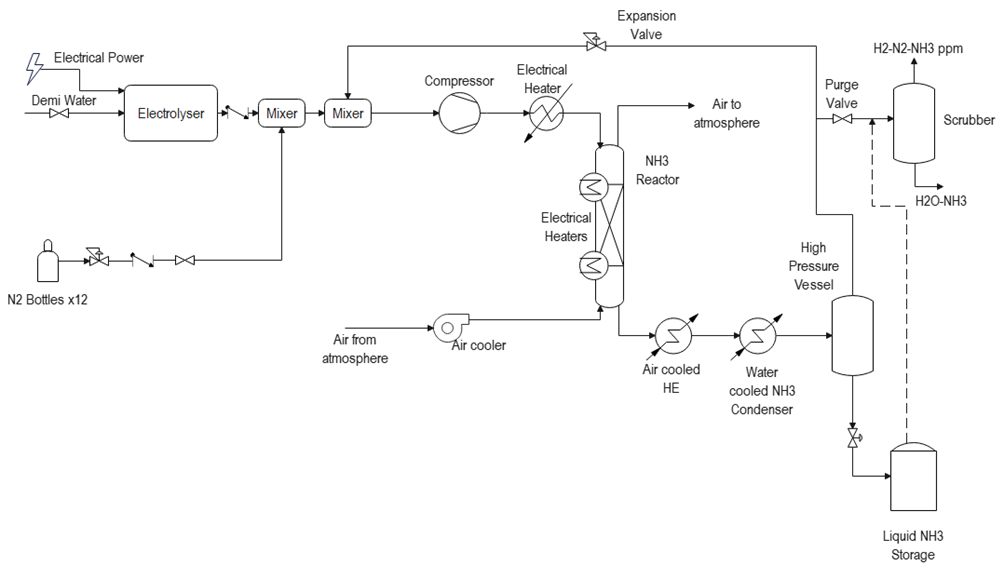

The cycle begins with hydrogen production through an electrolyzer, which operates at a maximum capacity of 15 kWel to generate up to 3 Nm3/h of H2 at 8 barg from water as the feedstock.

For initial feasibility tests, nitrogen is supplied from nitrogen bottles with a purity of 99.9998 vol%. To be compliant with the electrolyser working pressure, the high-pressure nitrogen is reduced to 8 barg.

The recycle stream, consisting of unreacted hydrogen, nitrogen, and any remaining ammonia, is mixed with the fresh hydrogen and nitrogen streams.

Then, this mixture is fed into a compressor, to raise the pressure of 80 barg required by the catalytic reactor. During compression, the gas heats up, and a subsequent electrical heater further elevates the temperature to meet also the temperature target imposed by the reactor.

The reactor features a fixed bed, tube-in-tube design. The inner high-pressure tube contains a second-generation iron-based catalyst, while the outer tube includes two electrical heating coils wrapped around the inner tube and allows air to flow through the space between the tubes. This design facilitates both heating during start-up and cooling during steady-state operation. The electrical heaters placed on the reactor enable rapid start-up by providing the activation energy necessary for the reaction. Once the reaction becomes self-sustaining, the heaters are switched off and are only reactivated during start-ups or significant temperature adjustments.

At the reactor outlet, the products are initially cooled to 60°C using an air heat exchanger. The mixture is then cooled to 15°C through a water heat exchanger. At this lower temperature, a large portion of the produced ammonia condenses, which is subsequently collected and stored in a pressure vessel.

A fraction of the gaseous phase exiting the condenser may be removed via a purge valve. The purge serves two purposes: regulating the pressure in the high-pressure section and removing unwanted impurities, such as argon from nitrogen bottles or less pure nitrogen supplied by the PSA unit.

The remaining gaseous mixture is then recycled through an expansion valve to adjust its pressure to match that of the incoming hydrogen and nitrogen streams.

A scrubbing system with a 1 m3 water-filled tank is included as a safety measure. This system serves to prevent the release of ammonia into the atmosphere during the purging process and acts as a safeguard in case of a malfunction in the pure ammonia storage system.

Scientific Coordinator: Loredana Magistri