In the framework of the PUMP-HEAT research project, the Thermochemical Power Group (TPG) of the University of Genoa, built a facility to study innovative solutions to increase flexibility of gas turbine combined cycles (GTCCs) through compressor inlet conditioning via heat pump (HP) (inlet heating/cooling) and coupled with a dedicated thermal energy storage (TES).

The test rig facility includes two main blocks: real hardware installed in the lab and a real-time simulation engine. The ensemble of hardware and dynamic model creates the cyberphysical system of a PUMPHEAT gas turbine combined cycle (GTCC). Focusing on the installed hardware, it consists of a micro gas turbine (mGT), a HP, one TES, several valves, pumps and heat exchangers (HXs). Regarding the real hardware block, data acquisition and control system is developed in NI Labview environment.

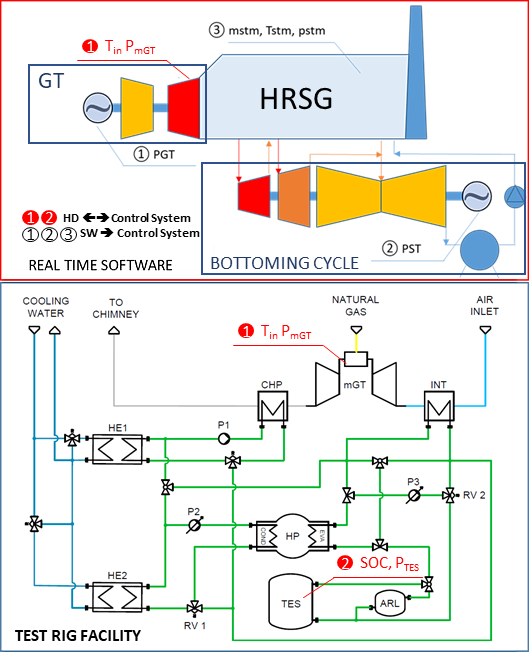

In the following, a schematic representation of the real-time software, which emulates an actual GTCC, is provided together with the connection points with the real facility, shown at the bottom of the figure. The real-time steam bottoming cycle dynamic model as well as the overall cyber control system are developed in Matlab-Simulink. The NI Labview system and the Matlab-Simulink model share information in real-time through a dedicated UDP communication system. Moreover, the plant P&ID integrating all physical components installed in the plant is reported.

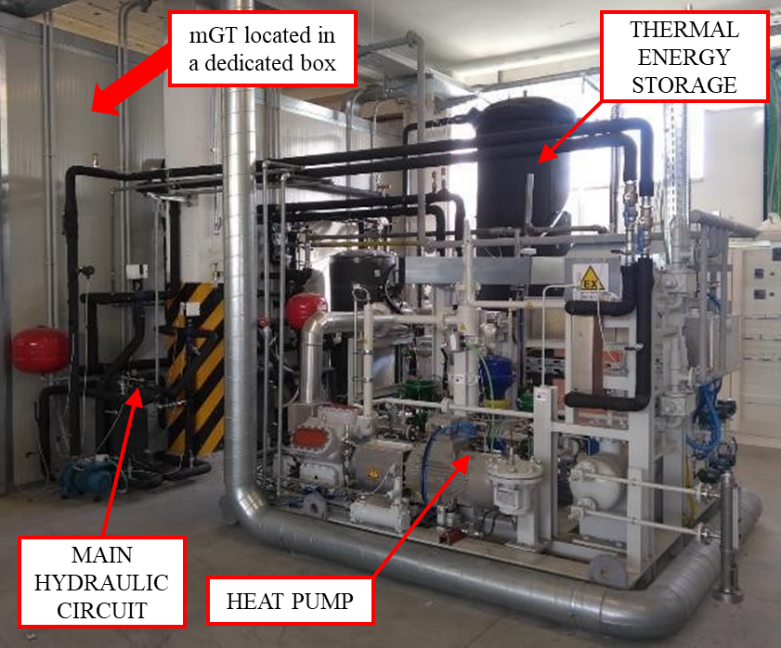

The following picture shows the main physical components of the cyber-physical system, which are:

- Turbec T100 micro gas turbine (mGT),

- Inlet conditioning heat exchanger (INT),

- 10 kWel heat pump (HP) using butane as working fluid,

- Thermal energy storage (TES).

All these components are connected through a dedicated hydraulic circuit that has been designed to reach maximum experimental flexibility: by acting on the numerous three-way valves, several sub-circuits can be activated to perform tests emulating different operating conditions.

Scientific Coordinator: Prof. Alberto Traverso